服务热线

4001-123-456

4001-123-456

4001-123-456

4001-123-456

CATEGORY

Single pulse power supply product uses:

Electroplating industry:suitable for precision surface treatment processes of precious metal electroplating,circuit board electroplating,gold plating,silver,rhodium,palladium,iron and other high-end products.

Electropolishing and deburring industry:pulse electrochemical polishing,plasma polishing,etc.

Electrical machining industry:pulse electrochemical precision machining and precision etching are aminly used to process precision devices with high hardness.

Special industries:nano electrodeposition,precious metal electrolysis,etc.

1. Single pulse power supply product uses:

Electroplating industry: suitable for precision surface treatment processes of precious metal electroplating, circuit board electroplating, gold plating, silver, rhodium, palladium, iron and other high-end products.

Electropolishing and deburring industry: pulse electrochemical polishing, plasma plasma polishing, etc.

Electrical machining industry: Pulse electrochemical precision machining and precision etching are mainly used to process precision devices with high hardness.

Special industries: nanoelectrodeposition, precious metal electrolysis, etc.

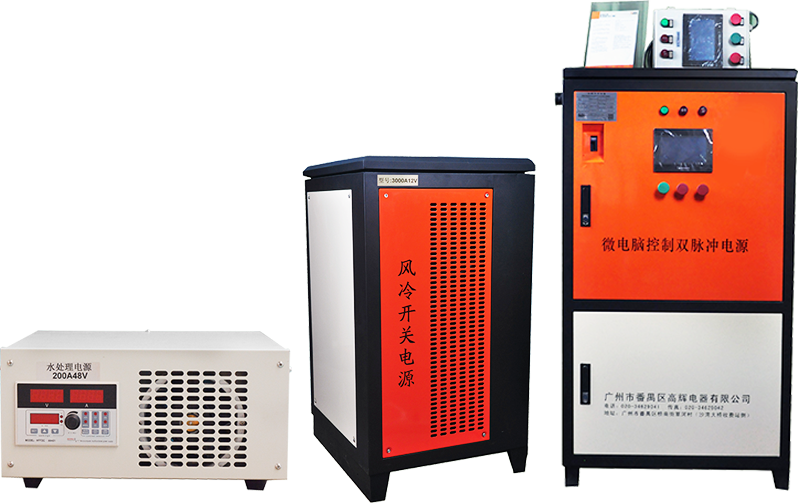

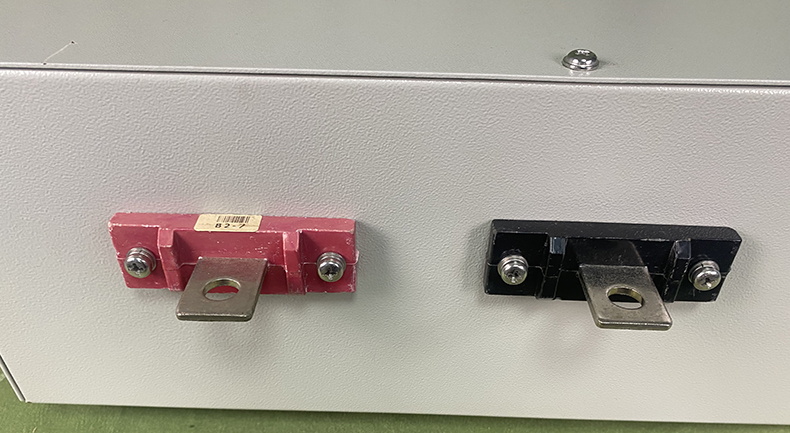

Characteristics of double pulse power supply

1.The adjustable double-pulse power supply uses a color touch human-machine interface display control.

2.The touch screen human-machine interface has functions such as voltage or current setting,frequency setting,duty cycle setting and mult-time setting.

3.The touch screen human-machine interface has an external interface communication interface.Equipped with RS-485(MODBUS protocol)local control and remote control switching function.

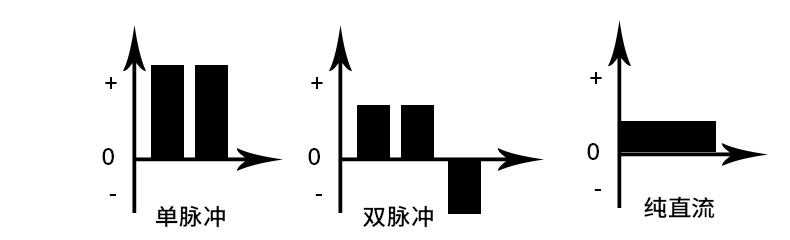

Single Pulse Power Waveform Display

Characteristics of pulse power supply

1.High-frequency pulse power supply is suitable for electroplating gold,silver,nickel,tin and alloys,which can significantly improve the functionality of the coatin;when used for protective-decorative electroplating(decorative=gold),it can make the coating uniform in color,bright,and corrosion-resistant;It has strong properties;when the pulse power supply od used to purity of the precious matals will be higher.Pulse power supply is superior to traditional electroplating Power supply and is the develipment direction of electroplating power supply.

2.The double-pulse power supply plating is more detailed and has a better finish than the single-pulse power supply.The anode dissolution of the reverse pulse of the dual pulse power supply causes the metal ion concentration on the cathode surface to rise rapidly,which is conducive to the use of high pulse current density in the subsequent cathode cycle,so the coating is dense,bright and has low porosity,the anode stripping of the reverse pulse of the double pulse power supply greatly reduces the attachment of organic impurities (including brightener) in the coating,so the coating has high purity and strong resistance to discoloration

3.Digital pulse power supply has the following waveforms:DC,positive pulse,negative pulse,positive and negative ppulse,negative DC,DC superimposed pulse

Basic principles of reversing pulse plating

During the pulse electroplating process,when the current is turned on,the electrochemical polarization increases,the metal ions near the cathode area are fully deposited,and the coating ctrstallizes finely and brightly;when the current is turned off,the discharge ions near the cathode area return to their initial concentration.Concentration polarization is eliminated.

Advantages of periodic commutation pulse plating

1.The reverse pulse current improves the thickness distribution of the coating,resulting in uniform coating thickness and good flatness.

rise rapidly,which is conducive to the use of high pulse current density in the subsequent cathode cycle,and

the high pulse current density makes the formation speed of crystal nuclei greater than the growth speed

of the crystal.Therefore,the coating is dense,bright and has low porosity.

3.The reverse pulse anodic stripping greatly reduces the adhesion of organic impurities(including

brighteners)in the coating,so the coating has high purity and strong resistance to discoloration.This is particularly prominent in cyanide silver plating.

embrittlement(for example,the reverse pulse can remove co-deposited hydrogen during electrodeposition of palladium)or reduce internal stress.

cathode current efficiency.Therefore,appropriate pulse parameters will further accelerate the deposition speed of the coating.

Therefore,the performance indicators of the coating such as temperatures resistance,wear

resistance,welding,toughness,anti-corrosion,conductivity,anti-discoloration,smoothness,etc.are doubled and rare precious metals|(about 20%-50%)can be greatly saved and additives(such as bright cyanide silver plating is about 50%-80%)

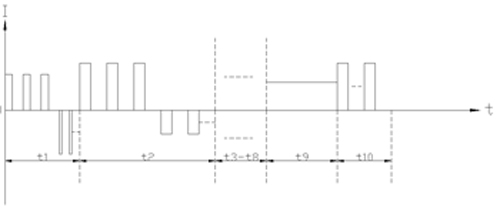

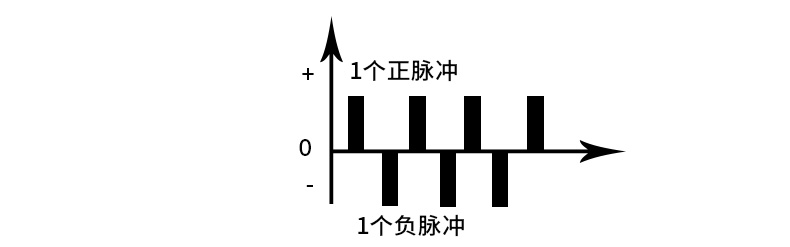

1.Periodic commutation pulse current waveform

Single pulse commtation with relevant off time.

That is ,a forward pulse with an off time is followed by a reverse pulse with an off time.This waveform has the advantages of both pulse and commutation,but the disadvantage is that pulse commutation function is imperfects.Its waveform is shown in the figure below.

2.Single pulse commutation without off time

That is,a forward without off time is followed by a reverse pulse by a recerse pulse without off time.This waveform has an obvious effect of improving the thickness distribution of the coating,but the effect of improving the crystallization of the coating is not ideal,and is generally not suitable for precious metal plating.Its waveform is shown in the figure below.

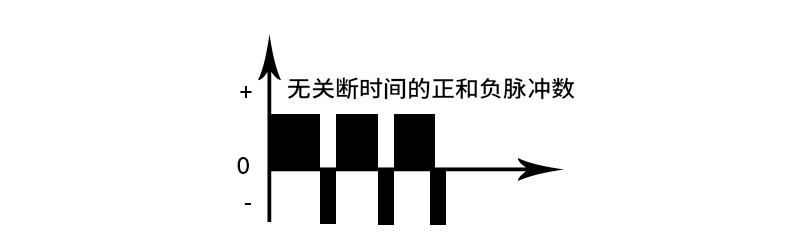

3.Multiple pulse commutation

That is, a set of forward pulses is followed by a set of reverse pulses (note: both forward and reverse pulses are group waves rather than single waveforms). This waveform is a typical periodic commutation pulse waveform and has the ability to improve the coating thickness distribution. It has the dual effect of improving the crystallization condition of the coating and is most widely used in functional electroplating. Its waveform is shown in the figure below.

4.sets of pulse commutation

Referred to as multi-pulse,it adds programmable functions on the basis of pulsating commutation.The pulse parameters used in each in program or period can be different.However,after the parameters of ordinary pulsating pulse commutation are adjusted,until the electroplating once the process is over,there will be no more changes.Its waveform is shown in the figure below.