Do you know the harm of the illegal electroplating process?

You know what?

Illegal electroplating equipment manufacturers because of the imperfect pollution treatment mechanism, great harm to the environment and the health of the surrounding masses.

One is air pollution: a large amount of chemical drugs such as strong acid, strong alkali, salt, organic solvent and so on are used in electroplating production. In the process of operation, a large number of toxic and harmful gases will be emitted. For example, hydrofluoric acid in the air smoke, steam has a very strong corrosive and toxic; chromium electroplating will send out a large number of chromium fog, chromium compounds can cause skin ulcers, anemia, nephritis and neuritis, and other diseases, and have the role of carcinogenesis and induced gene mutation.

The two is water pollution: the main source of zinc in electroplating and metal processing wastewater is electroplating or pickling towing fluid. The pollutants are then transferred to rinsing water by metal rinsing. The pickling process involves immersing metal (zinc or copper) in strong acid first to remove oxide from the surface, then immersing it in brightener containing strong chromate. The wastewater contains a large number of hydrochloric acid, zinc, copper and other heavy metal ions and organic brighteners, which are toxic, and some also contain carcinogenic, teratogenic and mutagenic toxic substances, which are very harmful to human beings.

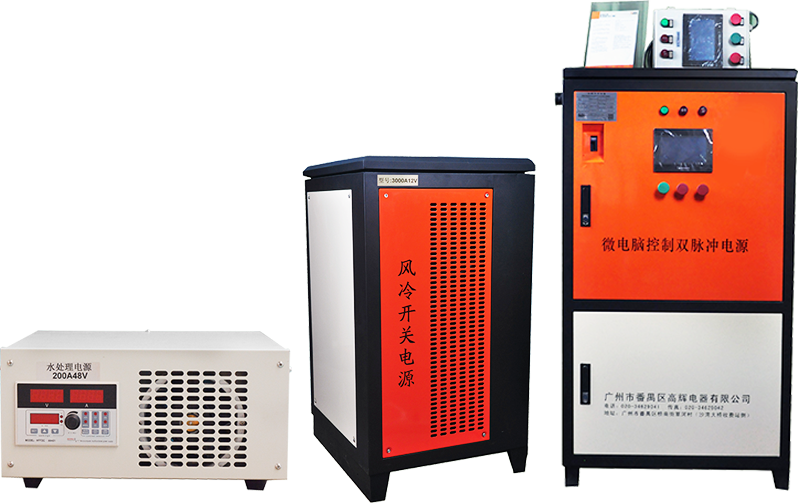

Electroplating equipment manufacturer

Three is the dust hazard: most hardware workpiece must be polished and mechanically polished before electroplating; in addition, in order to remove the castings, forgings or heat treatment of the surface of the surface of the slag, molding sand, oxide skin and other impurities, it is also required to sandblasting treatment. A large amount of dust, such as silicon, chromium, aluminum, iron, copper and linen, will be produced during these operations.

Four is the existence of explosion danger: the organic solvent is often used to degrease the workpiece in electroplating production. The commonly used organic solvents are gasoline, kerosene, acetone, benzene, trichloroethylene and carbon tetrachloride. In addition, the old coating is removed with the paint remover and the coating is closed with the cover light (closed) paint, and a large amount of two is contained in the paint remover. Chloromethane and other organic solvents also contain a variety of organic solvents in the light (closed) lacquer. Gasoline, kerosene, benzene, and some other organic solvents have low flash points and are volatile in the air. Fire and explosion will occur when the mixture of steam and air reaches the lower limit of the explosion.